When something transitions from physical to digital, it becomes immaterial, making it much easier to manipulate, transform, and build upon. Editing a photo in Photoshop is far simpler than doing it by hand on a physical photograph. The same applies to digital art—making changes to an artwork in Procreate is easier than doing the same changes on a piece of paper or canvas. Similarly, editing text in Word is much more convenient than using a pen and paper.

We can see a similar pattern unfold every time something becomes digital. This has happened with music, video, design, DNA, and more, opening new possibilities for improvements and accelerating innovation.

But what about things that are harder to digitise? Can we, for example, digitise a bridge? And not just a generic bridge, but that one specific bridge thousands of people cross every day?

Here is where digital twins come in. Digital twins promise to close the gap between the real and digital worlds, bringing into the virtual realm real-world objects, processes, and systems that were previously hard to digitise. They are already being used in various industries as one of the core technologies of Industry 4.0 and smart manufacturing. And soon, you might have one too, if you don’t already.

But what exactly is a digital twin? What are they used for? We will explore these and other questions in this article and see how digital twins blur the line between the real and the virtual.

But first, what is a digital twin?

Before we start exploring digital twins, it is important to clarify what we mean by this term.

A digital twin is a digital representation of a specific physical object, process, or system. These digital replicas are as true-to-reality as possible and are continuously updated to reflect the current state of their real-world counterpart. However, this is not only a one-way communication from the real world to the digital. Digital twins offer additional features and services, such as monitoring, simulations, and more, and can also affect their real-world counterparts.

Anything can have a digital twin—a factory, a machine, an entire department. Even a human can have their own digital twins.

Digital twins have become a buzzword in recent years, especially if you work in the industry, where they are heavily associated with Industry 4.0 and smart manufacturing. Digital twins combine IoT, sensors, physics simulations, high-performance computing, and machine learning. Some digital twins can also include VR and metaverse, two other popular buzzwords.

It might seem that such a technologically advanced idea like digital twins is a recent invention. However, the concept of digital twins can be traced back to the 1960s when NASA was not only pioneering space exploration but also inventing modern engineering practices. One of those practices was the pairing technology and that’s where we can see the roots of modern digital twins. Early digital twins can be seen in the replicas of crewed spacecraft used by ground crews to run simulations and study the spacecraft's behaviour. The most famous example of these early digital twins was during the Apollo 13 mission when engineers on the ground tirelessly experimented with a replica of the wounded spacecraft to find a way to bring the astronauts safely back to Earth.

What we know today as digital twins was introduced in 2002 by Michael Grieves, who applied this concept to manufacturing and business. He suggested that a digital model of a product, constantly updated with information from the real world, should accompany the physical item through its development. The term "digital twin" came from John Vickers, a NASA employee, who first used it in 2010 as part of a technology roadmap report for the space agency.

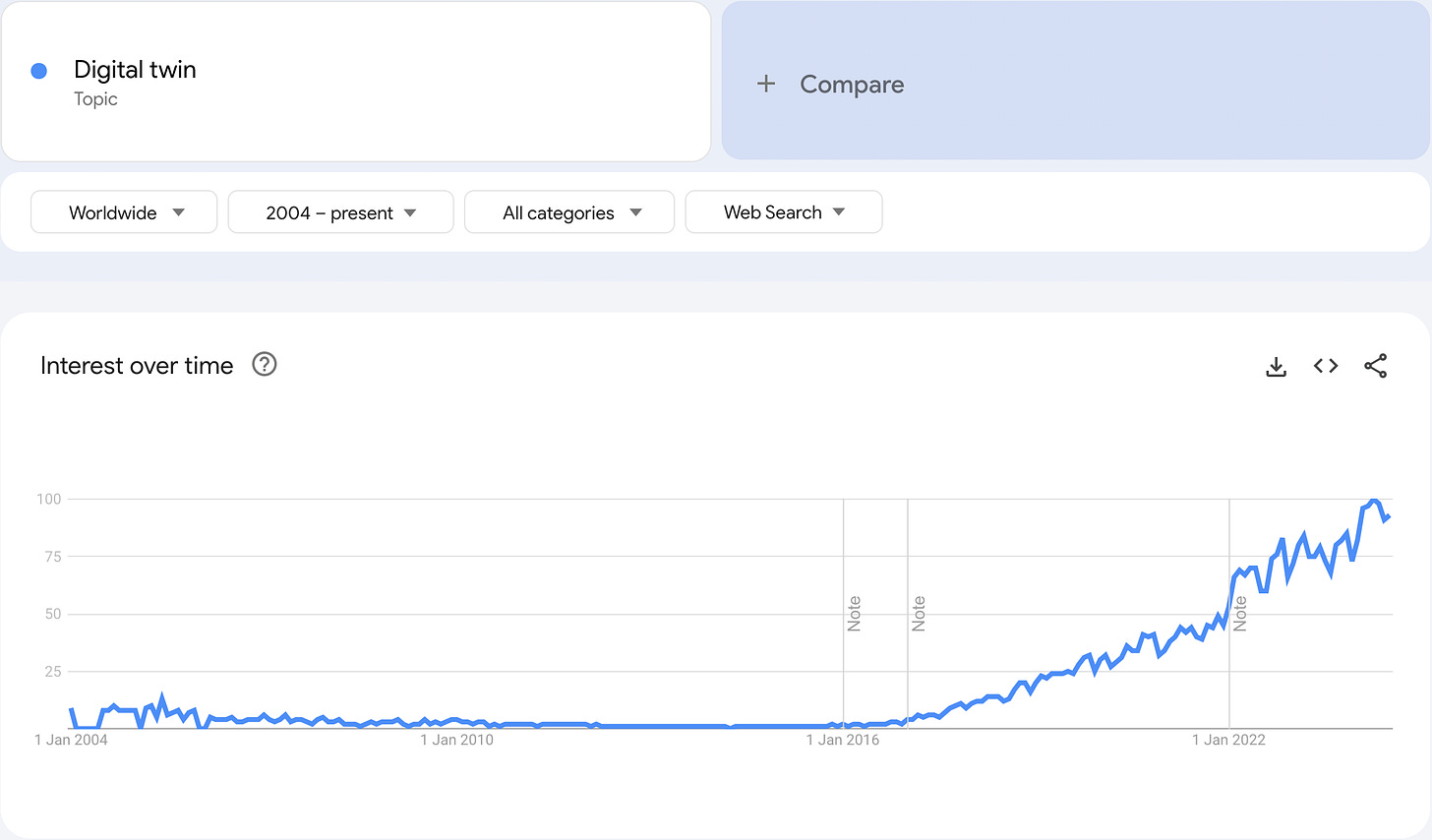

When we look at Google Trends results for “digital twin”, we can see the concept started to gain traction in 2016 which seems to be correlated with the increased interest in VR. Also around that time, other components of digital twins, such as IoT and machine learning, started to gain more attention.

Today, digital twins are an emergent and growing market. It contains big names from the industrial and tech sectors, such as General Electric Company, IBM, Microsoft, Siemens, Amazon, Nvidia, Oracle and ABB, as well as an entire cohort of startups hoping to carve out space for themselves.

According to PitchBook’s estimate, the market size reached $6.5 billion in 2022 and is projected to grow to $15.6 billion within the next couple of years. Grand View Research is more optimistic and predicts the worldwide market for digital twins to reach $86 billion by 2028.

How does a digital twin work?

Let's see how a digital twin works by creating a digital twin of an industrial robotic arm. This digital twin will be a detailed 3D model that accurately represents the robot, its joints, and its movements. The real-world robot has built-in sensors that measure everything—the position of each joint, the speed of the arm's movements, the current drawn by each motor, their temperature, and more. All the data from those sensors is continuously sent to the digital twin. When the robot moves, the virtual robot moves too. At any point in time, the digital twin mirrors as close as it is possible to its real-world counterpart.

The important thing is that both the real-world object and its digital twin are connected. A physical object is monitored through various sensors that feed data to the digital twin, which then uses it to update its state and learn what is happening with its real-world counterpart. The frequency and accuracy of updates depend on what the digital twin represents—some will require updates every second, while others may be fine with updates every hour or every day.

Now that we have a digital twin of the robotic arm, what can we do with it? The simplest thing we can do is monitor the robot’s performance and get some reports back (a digital twin limited only to monitoring and reporting is sometimes known as a “digital shadow”).

But we can do more than that. A digital twin can provide extra services beyond basic monitoring and reporting. We can put the digital twin robot into a simulated environment and let it learn new skills. We can experiment with different grippers or change the motors and see what happens. Using a digital twin, we can test how fast the robot can safely move or how it will interact with other robots or in other environments. A digital twin could also be used in planning, providing decision support, or modifying the physical object.

A digital twin also needs to, in some way, affect the physical object. For example, a digital twin of a jet engine could use control units to change the fuel mixture to make the engine more efficient. If we are dealing with a digital twin of an organisation, a human might be required to implement changes suggested by the digital twin. In the case of our example robot, a digital twin can learn new skills which then are uploaded to the real robot. In any case, the digital twin has the ability to affect its real-world counterpart.

Everything can have a digital twin…

Any physical object or process that can be constantly measured can be represented as a digital twin.

We can have digital twins for buildings and infrastructure such as bridges and tunnels to constantly monitor their state and to predict and schedule maintenance work. A business can create a digital twin of their factory and use it to experiment with different approaches to improve production quality, all while having a perfect view of the current state of the production lines and supplies.

Cities can use digital twins to better understand how they work and optimize infrastructure, utilities, and services. A digital twin of a city can simulate all aspects of urban life, from managing traffic and waste to urban growth and planning. They could help inform decision-makers on which policies or projects to pursue, leading to more efficient and effective urban management.

Digital twins can also be used in healthcare. Doctors can use accurate and up-to-date models of patients to guide them in planning therapies or preparing for surgeries. Digital twins also have the potential to improve drug development processes.

Basically, any process or object from any sector, from agriculture to energy and aerospace, can be represented by a digital twin. Even immaterial things like computer networks or organisations can have digital twins. Some even dream big and imagine digital twins of much larger and more complex systems, like entire economies or even a digital twin of Earth. In fact, Nvidia has a digital twin of Earth designed specifically for weather forecasting. As long there is a way to measure a system, create its digital representation and be able to affect its state or behaviour, anything can have a digital twin.

Once a digital twin is created, a physical object or process becomes digital. It then becomes much easier to manipulate and transform. With a digital twin, we can test things before they are rolled out to the real world. We can replay system behaviour based on historical data, which can be useful in root-cause analysis if something goes wrong. We can run numerous cost-effective "what-if" scenarios and simulations. Digital twins can also be used to train new operators on virtual processes before letting them work on the actual real-life processes.

However useful and exciting digital twins are, we also need to acknowledge their limitations.

Real-world objects and processes are complex systems, making them challenging to model as digital twins. The quality of a digital twin highly depends on the quality and quantity of data coming from its real-world counterpart. This data can often be sparse and noisy. Additionally, observations often need to be made indirectly, as we sometimes cannot be inside the object we want to measure. Some changes might not be picked up by sensors, which over time can have a dramatic effect on the digital twin. If the data is not accurate or too sparse, the digital model and the real-world object will drift apart, and the insights provided by the digital twin will be useless.

Better sensors, along with improved data cleaning methods and more accurate predictive models, combined with more powerful computers, could help make digital models more precise and in sync with the real world. However, there will always be some differences between the real world and the virtual world.

…including humans

Every physical object can have a digital twin. That also includes humans which opens numerous interesting ideas and thought-provoking possibilities.

Chances are, you already have a digital twin. If you own a smartwatch or any other fitness tracker that sends data about your health to an app, that app has built a digital twin of your health, constantly synchronizing with the state of your body. Your bank might have created a digital twin to model your financial activities. Even your activity on social media can be used to create a digital twin of your online presence and behaviour.

With the emergence of generative AI and large language models, a new possibility has opened—we can now quite easily train an AI to mimic a specific human and thus act as their digital twin. The pieces are already there, they just need to be connected. A large language model can be fed with text messages and transcripts and instructed to respond like the target person. Their voice can be cloned from a short audio sample and diffusion models can generate new pictures of them. Within seconds, someone can make a virtual clone of any person, given they provide enough data about the person to be cloned. Soon, we might start to see startups offering digital twins of real people.

The first to use them will most likely be social media influencers. A social media influencer could create a replica of themselves and use it to engage with their followers. With audiences numbering in the thousands or millions, it is practically impossible to reply to every message or comment. But with a digital twin, scaling interactions to a vast number of people becomes more realistic. While one twin handles comments and messages, another could be doing short calls with fans. There are already influencers experimenting with this idea and there will be more of them soon.

From there, the digital twin services could trickle down and start being used by ordinary people. We already have early forms of digital twins for our health and finances but what other digital twins can we have? Imagine a dating digital twin that talks to other people (or other digital twins) on dating apps. Perhaps we can have a digital twin for our careers, advising us on what steps to take to move to a new position. Maybe each student would have their learning twin recommending effective learning methods tailored specifically for them. How far can we go in digitising ourselves?

There is a possibility that each one of us will have not one but a network of digital twins, each representing a different aspect of our lives. Some of them might even have some level of agency and be allowed to act on our behalf which raises interesting questions. How many actions taken by the digital twin can be attributed to the physical person? Who will take the responsibility for the actions of the digital twin? How legally binding will contracts signed by a digital twin be? What should happen if a digital twin does something illegal?

Moreover, what should be done with someone’s digital twins when they die? Will we leave them inactive, similar to what happens today with social media accounts acting like digital gravestones? Will there be a legal requirement to terminate all digital twins of the deceased person? Or will we keep them active, allowing the deceased person to exist in a sort of digital afterlife?

Digital twins are the natural next step in our pursuits of digitising everything. We have already made this transition from physical to digital with photos, videos, music, DNA, and even with our relationships with social media. With digital twins, we can bring now what previously resisted digitalisation into the digital world, blurring the line between the real world and the virtual world.

Thanks for reading. If you enjoyed this post, please click the ❤️ button or share it.

Humanity Redefined sheds light on the bleeding edge of technology and how advancements in AI, robotics, and biotech can usher in abundance, expand humanity's horizons, and redefine what it means to be human.

A big thank you to my paid subscribers, to my Patrons: whmr, Florian, dux, Eric, Preppikoma and Andrew, and to everyone who supports my work on Ko-Fi. Thank you for the support!

My DMs are open to all subscribers. Feel free to drop me a message, share feedback, or just say "hi!"

Excellent summary of the state of Digital Twins!